Abrasive blasting is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface, shape a surface, or remove surface contaminants. A pressurized fluid, typically air, or a centrifugal wheel is used to propel the media.

Abrasive blasting of steel substrates can provide the best possible surface preparation for coatings adhesion. If done properly, abrasive blasting thoroughly cleans the surface and creates a surface profile for mechanical adhesion. To achieve the economy available through abrasive blasting, the operator must maintain the productivity and efficiency of the cleaning system through careful attention to all of its components.

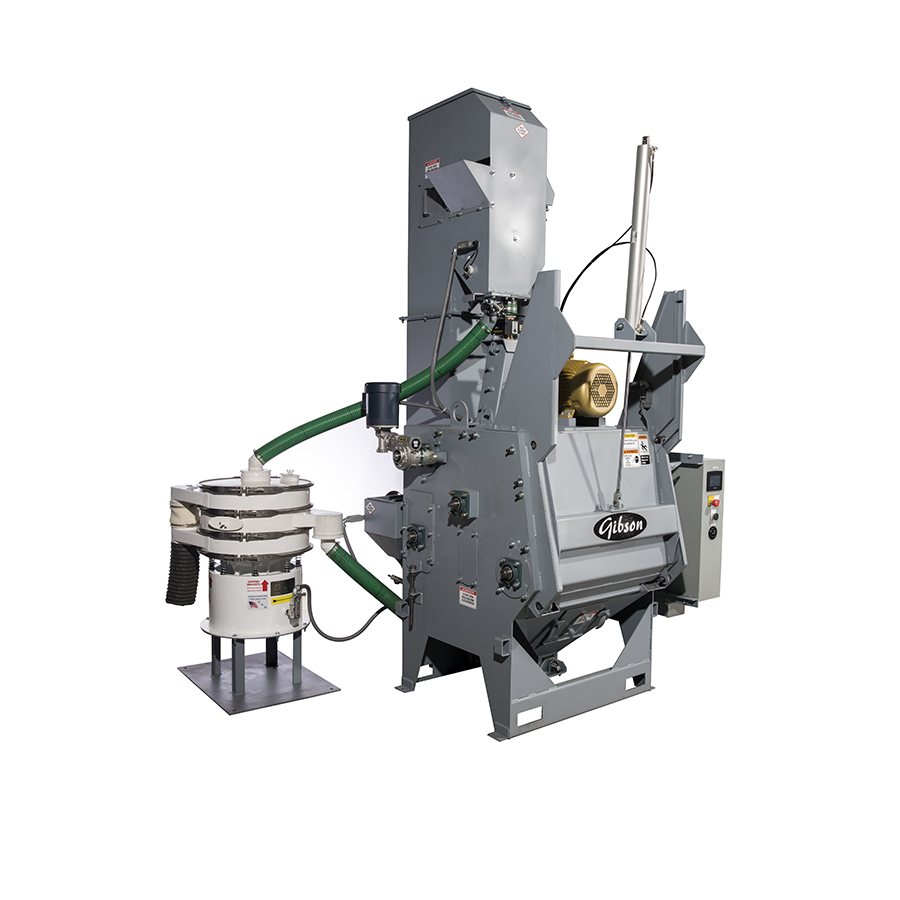

All Wheel Blast Cleaning Machines include these basic design criteria:

- Blast Wheel(s) – The wheel(s) propels or throw(s) the abrasive media.

- Work Handling system – depending on the design type of machine this may be rubber tumbling mill apron belt, fixture of hooks or pockets, hanger with hooks, rotary table or tables, or pass-through roller or belt conveyor that transfer the work piece(s) through the blast zone.

- Electrical System – The wiring, controls, and motors to power and safely operate the system.

- Abrasive Reclaim System- Transfers the abrasive mix back to the Abrasive Storage Hopper.

- Separation System – The method that the machine has to remove contaminated waste, broken down media or dust from the reusable “good” abrasive.

- Abrasive Storage System – The storage hopper system that effectively provides consistent media to the blast wheel.

- Ventilation System – The Dust Collection System provides negative pressure to the system to assure dust free operation as well as performs the pneumatic separation of the abrasive and waste mix.