Shot peening is a cold working process used to produce a compressive residual stress layer and modify mechanical properties of metals and composites. It entails impacting a surface with shot (round metallic, glass, or ceramic particles) with force sufficient to create plastic deformation.

In machining, shot peening is used to strengthen and relieve stress in components like steel automobile crankshafts and connecting rods. In architecture it provides a muted finish to metal.

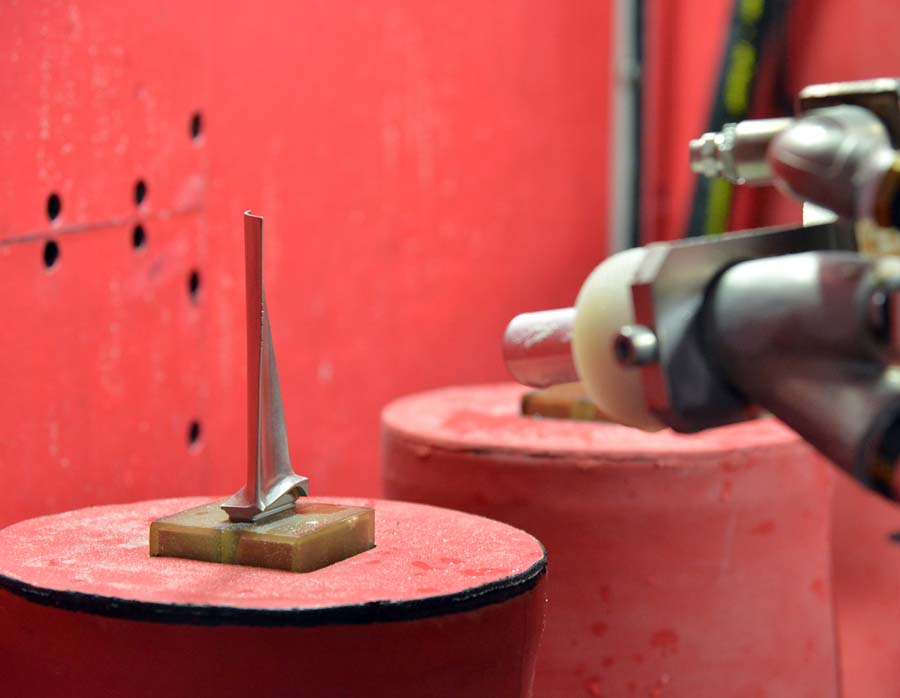

FinTec works with our OEMS to custom design each Shot Peen machine around your unique application. Our focus is to always supply a robust, user friendly machine that allows you to reach your desired peening result. We strive to make it easy to train your operators to not only run the machine but also maintain the machine. From turbine blades to cam shafts, and everything in between, we focus on designing a machine that lasts- one that is operator and maintenance friendly