Abrasive air blast cabinets are utilized all across industry to either obtain a desired surface finish and to strip or remove coatings. Pressure cabinets provide the fastest means of blasting due to the fact that all of the air pressure is utilized to flow the abrasive to the nozzle and propel it at the work surface. Typically, Pressure cabinets are more efficient than suction cabinets.

Pressure Blast Cabinet Pros

- HIGH production – The greatest benefit to a pressure fed blast cabinet is that it is 3 – 4 times as fast at cleaning a product surface

- Better cleaning ability – Since a pressure blast cabinet provides media at a greater force, it will clean products that have a greater degree of surface contaminant

- Can be used with metallic medias – Metallic medias can be required to achieve the surface profile in certain applications and, if they are needed, a pressure blast cabinet is often recommended

Pressure Blast Cabinet Cons

- Greater initial expense – A pressure cabinet will cost considerably more initially than a suction blast cabinet. This is largely due to design requirements that are needed to support pressure blasting.

- Faster Component wear – Items like blast nozzles, cabinet linings, and window covers will wear faster because the media will be moving at a higher force and speed compared to a suction fed cabinet

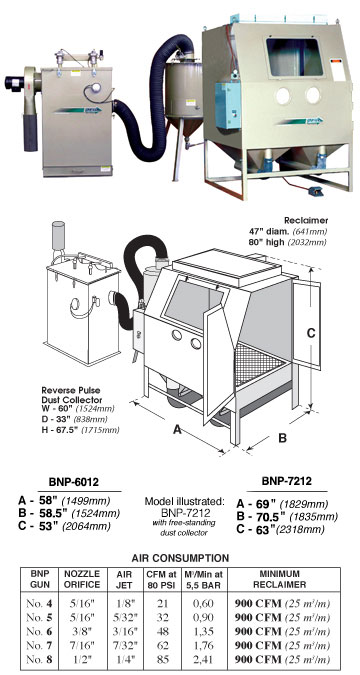

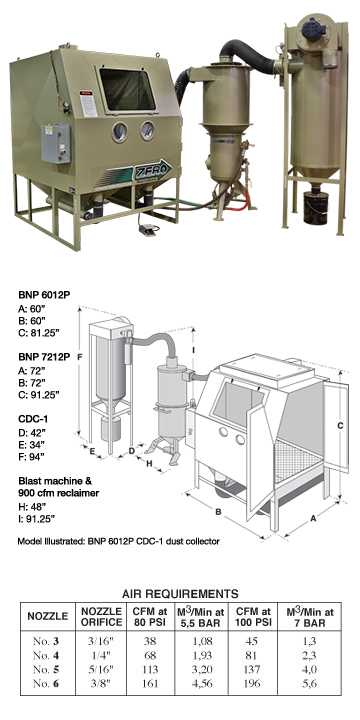

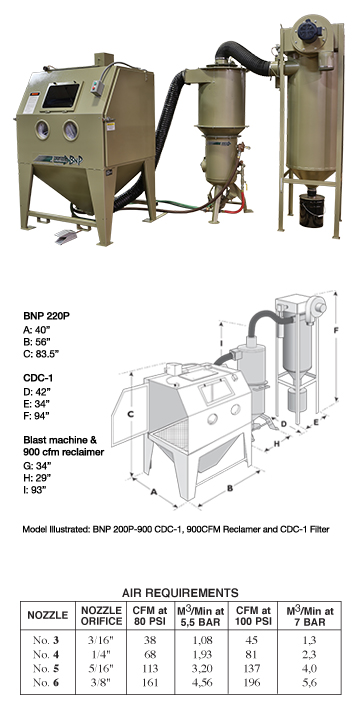

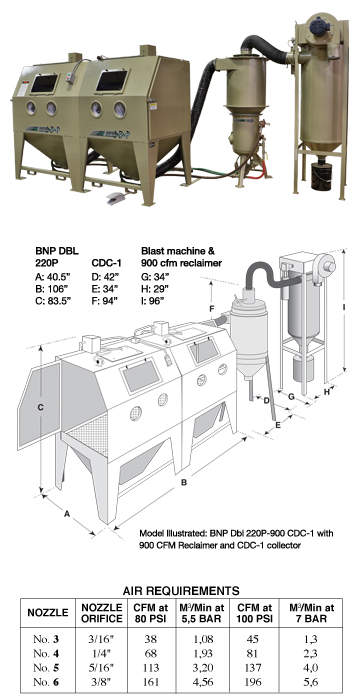

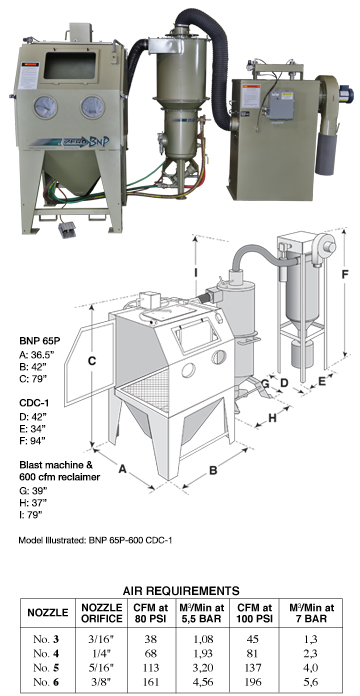

- Higher volume of air needed – A pressure blast cabinet will require much more air than a suction cabinet.