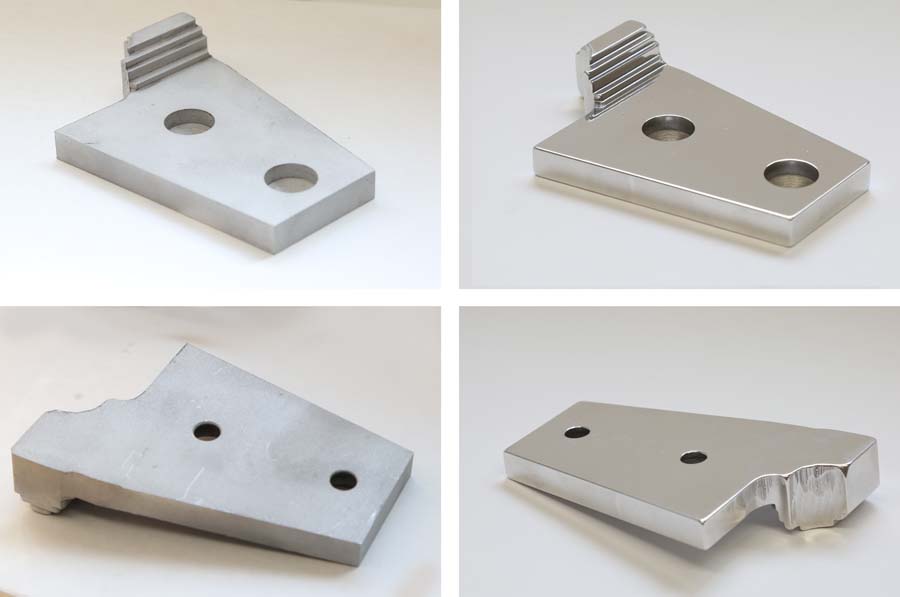

Centrifugal barrel finishing machines operate on a “Ferris Wheel” principal with a 1 to 1 ratio of barrel to turret rotation. Each one of 4 barrels is loaded full of parts, water and compound. During operation rotation of the turret creates a sliding force inside the barrel. This motion causes parts and media to contact each other in random an isotropic direction. The resulting finish is consistent across the entire surface of the part. We supply complete sample processing and we stock media and compounds needed to fit your application. High energy finishing is used extensively in aerospace, medical and additive manufacturing part processing.